It was a bit tricky to figure out the number of processors waiting for an operator, but it is solved.īecause the main parameter (number of processors and operators) are labels, they can be changed in the experimenter.

#ANYLOGIC VS FLEXSIM UPDATE#

But because this is not certain, the OnMessage on the processor is used to update the labels, every time an item enters or leave the queue or the processors starts or finish the process. If it would be sure that always a 3D view is open and makes a lot of screen refreshes, it could be use to update the labels on the processor. Some information is shown under the processor. The input of the processor is controlled depending on the number of operators. In general the user defines the number of processors and operators in two labels on the processor. There is a description in the model for some explanation. I built a small model where I tried to use the concept of this other simulators. copy processors, make connections, etc.) to make it easy for the user to modify the number of processors and operators. I agree with Steven, that there are ways to model the scenario with the Flexsim standards and use some automatically model building stuff (e.g.

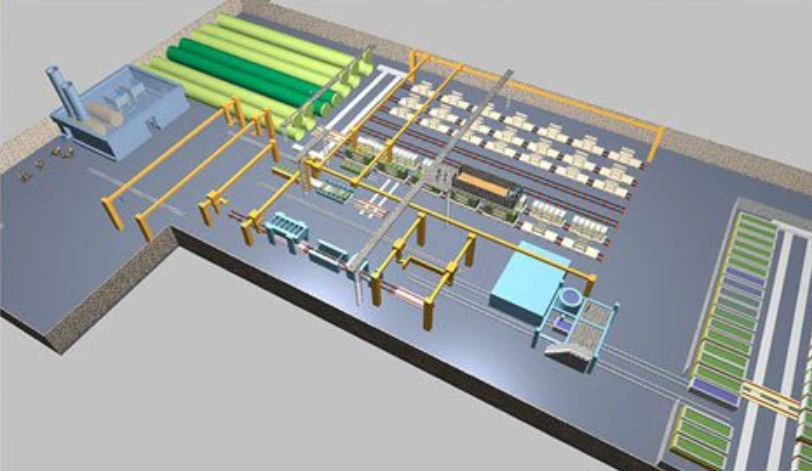

In Flexsim you can examine more scenarios in my eyes, but to model the simple scenario is a bit tricky, because Flexsim is designed in another way. The above examples are the first things which come to my mind. I am pretty sure there are more scenarios which are difficult to model in these simulators. I am not sure which data/statistics get collected in such a simulator, but I guess they are poor. Hardly visualization of the operators (maybe an icon appears is there is an operator at the processor). No information about the distance an operator travels. Not able to use the operator as a “transporter” (carry the item to the processors) and also does the setup/process. No modeling of the time the operator needs to get to the processor (ways).

They just check if the number of total operators is not used yet and just take one if available. Simulators which are only handle resources like operators as a number/variable are not able to simulate certain scenarios. I agree with Steven and David, that we speak here about two totally different model concepts. Any thoughts on simple ways to model this?

#ANYLOGIC VS FLEXSIM MANUAL#

This seems like it would involve a lot of manual port management and setup. There are also different operator types so I guess they need to be managed by individual type or to carry a Type-Label. This would possibly be an acceptable solution if the actual operator numbers were all that needed to be varied, however as processors that utilize operators can only process 1 flow item at a time we would need to create an arbitrary maximum number of processors to match. It was suggested that we could simply create an arbitrary maximum number of resources and just toggle them on and off in an experiment, as required - probably via a Global Variable. Our application requires us to be able to vary this quantity at run time or during setup for optimization or Monte Carlo runs which is quite easy in AnyLogic – the “resource quantity” attribute is set. However, instead of having discrete individual resources to manage, the resource pool merely has a total number of available resources and manages the number of idle vs utilized.

Resource pools play a similar role to the dispatchers in Flexsim– they facilitate the delegation of resources to tasks. Whilst in Flexsim resources are individually created and assigned to processes AnyLogic utilizes the concept of “resource pools”. They both handle resources at very different levels of fidelity. In direct comparisson with AnyLogic, there is one very notable difference in how AnyLogic and Flexsim handle resources. We're trying to replicate an existing AnyLogic model in Flexsim, as part of a Flexsim evaluation, but one issue is getting complicated.

0 kommentar(er)

0 kommentar(er)